Products

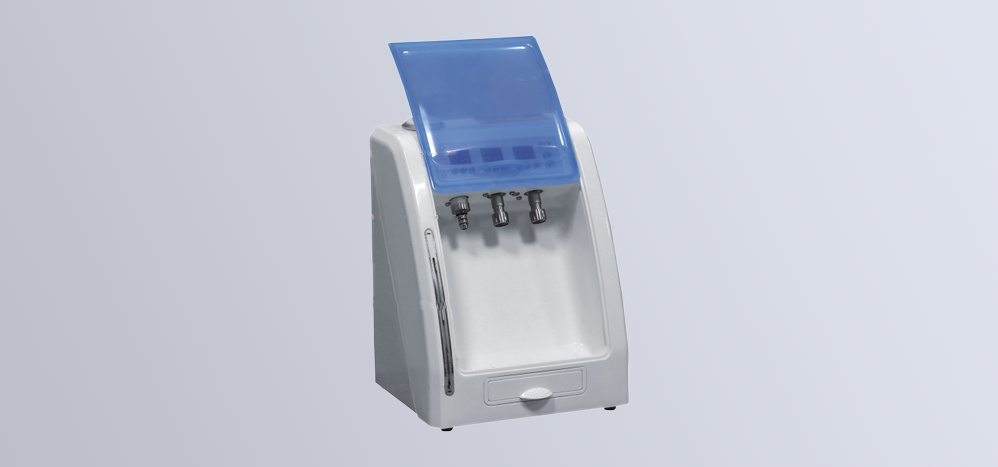

SKI-550 (Mobile) Dental Electric Suction System-Dental Instruments

Keywords:

Product

Category:

Variable frequency negative pressure suction machine

Product Summary

Product

Cleaning and disinfection procedures for dental instruments

1. Recycling: After the dental instruments are used, the English wastes are placed separately and recycled in time.

Dental instruments should be classified and placed according to the different materials, functions and processing methods of the instruments.

The recycling container should be cleaned, disinfected and dried after each use.

2. Cleaning method; manual cleaning, automatic cleaning machine cleaning, ultrasonic cleaning machine cleaning.

3. Basic principles of dental instrument cleaning:

① Dispose of in time after use;

②Dental instruments and other instruments with complex structure and many gaps should be cleaned by ultrasonic; ③Oral instruments with power supply and sophisticated and complex oral instruments should be cleaned manually; ④Removable instruments should be disassembled and cleaned separately, such as electric dental scaling ⑤The handle of the electric scaler should be cleaned manually; ⑥The cleaning water meets the requirements: the conductivity of the final rinsing water is ≤15us/cm, and the water temperature is 25℃; ⑦Select the appropriate cleaning agent according to the degree of pollution; Disinfection process, special infections should be disinfected first and then cleaned.

Cleaning quality standard:

Visually inspect or use a magnifying glass with a light source to inspect the dried oral instruments.

There should be no residual substances such as stains, water stains and rust spots on the surface of the instrument, the spiral structure, and the joints.

The unqualified instruments should be reprocessed, and the damaged or deformed instruments should be replaced in time.

There are no cracks and defects on the surface, and the joint mobility is good.

The tooth ends are well closed when the instrument is closed.

The latch is well secured and maintains tension.

The hub moves smoothly.

Disinfection: wet heat disinfection is preferred for physical disinfection, and 75% ethanol is commonly used for chemical disinfection.

Drying equipment and utensils should be selected for drying treatment, and the appropriate drying temperature should be selected according to the materials of the equipment and utensils; the drying temperature for metals is (70-90) ℃, and the drying temperature for plastics is (65-75) ℃. Instruments without drying equipment and heat-labile can be dried with a low-fiber wipe.

Dental instruments refer to various small portable tools specially used in dentistry, which are called dental instruments internationally. Dental medical instruments include dental handpieces, oral handpiece sterilizers, extraction forceps, dental elevators, dental picks and other surgical instruments, manual dental instruments, dental rotary instruments, dental injection instruments, and root canal instruments. The range of dental medical equipment is wide and there are many manufacturers. The corresponding international group ISO/TC106 SC4 is specially responsible for the standardization work in this area.

There are many standards involved in the products and components of dental instruments. The national and industrial standards included in the "Medical Instrument Standard Compilation Oral Instruments and Equipment Volume" published by China Standard Press (2002) are as follows: GB/T 5041--- -------------Dental grinding wheel GB/T 5042-------------Dental grinding head YY/T 0453------------ --General technical conditions for tooth extraction forceps YY/T 0170.1 ------------- Elevator: YY/T 0170.1------------T-shaped Elevator YY/T 0273 - ------------Dental amalgam blender YY/T 0275 -------------Amalgam filler YY/T 0274.1------ ------Dental Scaling Equipment YY/T 0274.2------------Dental Scaling Equipment Scaling YY/T 0278 ---------- ---Root canal filler YY/T 0295.4 -------------Dental forceps YY/T 0295.2 ------------- Plastic forceps YY 0302 -- -------------High speed dental bur YY 91014 -------------Dental probe YY 91019 -------------Dental Needle YY 91021 --------------Adult tooth extraction forceps YY 91022 --------------Children's tooth forceps YY 91044 --------- -----High-speed turbo dental drill YY 91045 --------------High-speed turbo dental drill head YY 91064 --------------Dental rotary instrument steel And carbide dental drill technical conditions YY 91010 --------------Dental rotary instruments matching dimensions YY 91011 -------------- Basic dimensions of dental rotary instruments and label

advantage:

A. The appearance is small and exquisite, does not occupy the clinic space, the operating system is simple and clear, and there is no need to change the dental chair pipeline, saving time, effort and cost.

B. High-power motor, super suction, comes with 3 imported straws that can adjust the strength and weakness.

C, sound insulation design, low noise.

D. Electronic display screen, large-capacity water storage bottle and water level detection.

E. One-key intelligent sewage discharge.

F. Built-in integrated circuit board control, microcrystalline panel, and partition design is convenient and durable.

G. Advanced silent wheels, with lock design, comfortable and durable.

Product

Cleaning and disinfection procedures for dental instruments

1. Recycling: After the dental instruments are used, the English wastes are placed separately and recycled in time.

Dental instruments should be classified and placed according to the different materials, functions and processing methods of the instruments.

The recycling container should be cleaned, disinfected and dried after each use.

2. Cleaning method; manual cleaning, automatic cleaning machine cleaning, ultrasonic cleaning machine cleaning.

3. Basic principles of dental instrument cleaning:

① Dispose of in time after use;

②Dental instruments and other instruments with complex structure and many gaps should be cleaned by ultrasonic; ③Oral instruments with power supply and sophisticated and complex oral instruments should be cleaned manually; ④Removable instruments should be disassembled and cleaned separately, such as electric dental scaling ⑤The handle of the electric scaler should be cleaned manually; ⑥The cleaning water meets the requirements: the conductivity of the final rinsing water is ≤15us/cm, and the water temperature is 25℃; ⑦Select the appropriate cleaning agent according to the degree of pollution; Disinfection process, special infections should be disinfected first and then cleaned.

Cleaning quality standard:

Visually inspect or use a magnifying glass with a light source to inspect the dried oral instruments.

There should be no residual substances such as stains, water stains and rust spots on the surface of the instrument, the spiral structure, and the joints.

The unqualified instruments should be reprocessed, and the damaged or deformed instruments should be replaced in time.

There are no cracks and defects on the surface, and the joint mobility is good.

The tooth ends are well closed when the instrument is closed.

The latch is well secured and maintains tension.

The hub moves smoothly.

Disinfection: wet heat disinfection is preferred for physical disinfection, and 75% ethanol is commonly used for chemical disinfection.

Drying equipment and utensils should be selected for drying treatment, and the appropriate drying temperature should be selected according to the materials of the equipment and utensils; the drying temperature for metals is (70-90) ℃, and the drying temperature for plastics is (65-75) ℃. Instruments without drying equipment and heat-labile can be dried with a low-fiber wipe.

Dental instruments refer to various small portable tools specially used in dentistry, which are called dental instruments internationally. Dental medical instruments include dental handpieces, oral handpiece sterilizers, extraction forceps, dental elevators, dental picks and other surgical instruments, manual dental instruments, dental rotary instruments, dental injection instruments, and root canal instruments. The range of dental medical equipment is wide and there are many manufacturers. The corresponding international group ISO/TC106 SC4 is specially responsible for the standardization work in this area.

There are many standards involved in the products and components of dental instruments. The national and industrial standards included in the "Medical Instrument Standard Compilation Oral Instruments and Equipment Volume" published by China Standard Press (2002) are as follows: GB/T 5041--- -------------Dental grinding wheel GB/T 5042-------------Dental grinding head YY/T 0453------------ --General technical conditions for tooth extraction forceps YY/T 0170.1 ------------- Elevator: YY/T 0170.1------------T-shaped Elevator YY/T 0273 - ------------Dental amalgam blender YY/T 0275 -------------Amalgam filler YY/T 0274.1------ ------Dental Scaling Equipment YY/T 0274.2------------Dental Scaling Equipment Scaling YY/T 0278 ---------- ---Root canal filler YY/T 0295.4 -------------Dental forceps YY/T 0295.2 ------------- Plastic forceps YY 0302 -- -------------High speed dental bur YY 91014 -------------Dental probe YY 91019 -------------Dental Needle YY 91021 --------------Adult tooth extraction forceps YY 91022 --------------Children's tooth forceps YY 91044 --------- -----High-speed turbo dental drill YY 91045 --------------High-speed turbo dental drill head YY 91064 --------------Dental rotary instrument steel And carbide dental drill technical conditions YY 91010 --------------Dental rotary instruments matching dimensions YY 91011 -------------- Basic dimensions of dental rotary instruments and label

advantage:

A. The appearance is small and exquisite, does not occupy the clinic space, the operating system is simple and clear, and there is no need to change the dental chair pipeline, saving time, effort and cost.

B. High-power motor, super suction, comes with 3 imported straws that can adjust the strength and weakness.

C, sound insulation design, low noise.

D. Electronic display screen, large-capacity water storage bottle and water level detection.

E. One-key intelligent sewage discharge.

F. Built-in integrated circuit board control, microcrystalline panel, and partition design is convenient and durable.

G. Advanced silent wheels, with lock design, comfortable and durable.

Recommended Products

Consult Now

If you are interested in our products, please leave your email and we will contact you as soon as possible. Thank you!