Products

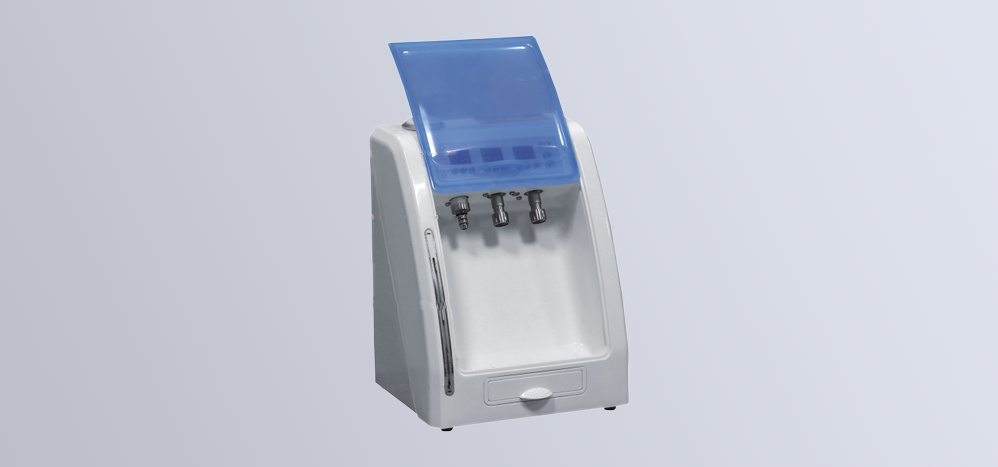

SKI brand 401 model medical sewage sterilizer (self-flow) - sewage treatment equipment

Keywords:

Product

Category:

Sewage treatment equipment

Product Summary

Product

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Product Specifications

Product material: 304 stainless steel

Scope of use: 6-10 dental chairs

Operating power: Self-priming (with pump): 750W Self-current (without pump): 180W

Power input: AC 220V

Product size: length 48CM* width 48CM* height 65CM

Sterilization method: ozone sterilization

Water inlet method: self-flow water inlet, self-priming water inlet

Net weight: self-priming 47kg, artesian 41kg

Quality inspection report number: E16-WT4453

Implementation standard:

GB9706.1-2007 "Medical Electrical Equipment Part 1: General Requirements for Safety"

GB18466-2005 "National Medical Institution Sewage Discharge Pretreatment Standard"

The sewage treatment equipment adopts membrane bioreactor (Membrane Bioreactor, referred to as MBR) technology, which is a new process combining biological treatment technology and membrane separation technology, replacing the secondary sedimentation tank in the traditional process. Solid-liquid separation can be used to obtain stable reclaimed water for direct use. The sewage treatment equipment can maintain a high concentration of microorganisms in the biological pool, and the residual sludge in the process is less, which can effectively remove ammonia nitrogen. Bacteria and viruses in water are largely removed, with low energy consumption and small footprint. In the 1970s, membrane bioreactors have been used in research on sewage and wastewater treatment in the United States, Japan, South Africa and many European countries. From domestic sewage (such as shower drainage, toilet drainage, laundry drainage, kitchen drainage, toilet drainage, etc.) and cooling water.

Process flow

Raw water→grid→regulating tank→lifting pump→bioreactor→circulating pump→membrane module→disinfection device→reclaimed water storage tank→reclaimed water water system process description

The sewage enters the conditioning tank through the grille and then enters the bioreactor through the lift pump. The aerator is turned on by the PLC controller for oxygenation. The effluent from the bioreactor enters the membrane separation treatment unit through the circulating pump, and the concentrated water returns to the conditioning tank. After the rapid mixing method of chlorination disinfection (sodium hypochlorite, bleaching powder, chlorine tablets), it enters the reclaimed water storage tank. The backwash pump uses the treated water in the cleaning tank to backwash the membrane treatment equipment, and the backwashed sewage returns to the adjustment tank. The opening and closing of the lift pump is controlled by the water level in the bioreactor. The filtration operation and backwashing operation of the membrane unit can be controlled automatically or manually. When the membrane unit needs chemical cleaning operation, close the water inlet valve and sewage circulation valve, open the chemical cleaning valve and chemical circulation valve, start the chemical liquid circulation pump, and carry out chemical cleaning operation.

Sewage treatment equipment is a kind of industrial equipment that can effectively treat domestic sewage and industrial wastewater in urban areas. It prevents sewage and pollutants from directly flowing into the water area, which is of great significance to improving the ecological environment, enhancing the quality of the city and promoting economic development. Buried sewage treatment equipment is suitable for domestic sewage and similar industrial organic Wastewater, such as organic sewage treatment in textile, beer, paper, leather, food, chemical and other industries, the main purpose of sewage treatment equipment is to treat domestic sewage and similar industrial organic wastewater to meet the water quality requirements for reuse, so that the wastewater can be reused. Resource utilization after processing.

The so-called primary sewage refers to the direct discharge of untreated domestic or industrial waste water from the city. The current utilization method is that the primary sewage directly enters the sewage source heat pump system for heat exchange, and the indoor cooling and heating of urban buildings are provided under the condition of consuming a small amount of electricity. There are several technical difficulties to be overcome in sewage reuse: clogging, corrosion, heat exchange efficiency.

Product

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Product Specifications

Product material: 304 stainless steel

Scope of use: 6-10 dental chairs

Operating power: Self-priming (with pump): 750W Self-current (without pump): 180W

Power input: AC 220V

Product size: length 48CM* width 48CM* height 65CM

Sterilization method: ozone sterilization

Water inlet method: self-flow water inlet, self-priming water inlet

Net weight: self-priming 47kg, artesian 41kg

Quality inspection report number: E16-WT4453

Implementation standard:

GB9706.1-2007 "Medical Electrical Equipment Part 1: General Requirements for Safety"

GB18466-2005 "National Medical Institution Sewage Discharge Pretreatment Standard"

The sewage treatment equipment adopts membrane bioreactor (Membrane Bioreactor, referred to as MBR) technology, which is a new process combining biological treatment technology and membrane separation technology, replacing the secondary sedimentation tank in the traditional process. Solid-liquid separation can be used to obtain stable reclaimed water for direct use. The sewage treatment equipment can maintain a high concentration of microorganisms in the biological pool, and the residual sludge in the process is less, which can effectively remove ammonia nitrogen. Bacteria and viruses in water are largely removed, with low energy consumption and small footprint. In the 1970s, membrane bioreactors have been used in research on sewage and wastewater treatment in the United States, Japan, South Africa and many European countries. From domestic sewage (such as shower drainage, toilet drainage, laundry drainage, kitchen drainage, toilet drainage, etc.) and cooling water.

Process flow

Raw water→grid→regulating tank→lifting pump→bioreactor→circulating pump→membrane module→disinfection device→reclaimed water storage tank→reclaimed water water system process description

The sewage enters the conditioning tank through the grille and then enters the bioreactor through the lift pump. The aerator is turned on by the PLC controller for oxygenation. The effluent from the bioreactor enters the membrane separation treatment unit through the circulating pump, and the concentrated water returns to the conditioning tank. After the rapid mixing method of chlorination disinfection (sodium hypochlorite, bleaching powder, chlorine tablets), it enters the reclaimed water storage tank. The backwash pump uses the treated water in the cleaning tank to backwash the membrane treatment equipment, and the backwashed sewage returns to the adjustment tank. The opening and closing of the lift pump is controlled by the water level in the bioreactor. The filtration operation and backwashing operation of the membrane unit can be controlled automatically or manually. When the membrane unit needs chemical cleaning operation, close the water inlet valve and sewage circulation valve, open the chemical cleaning valve and chemical circulation valve, start the chemical liquid circulation pump, and carry out chemical cleaning operation.

Sewage treatment equipment is a kind of industrial equipment that can effectively treat domestic sewage and industrial wastewater in urban areas. It prevents sewage and pollutants from directly flowing into the water area, which is of great significance to improving the ecological environment, enhancing the quality of the city and promoting economic development. Buried sewage treatment equipment is suitable for domestic sewage and similar industrial organic Wastewater, such as organic sewage treatment in textile, beer, paper, leather, food, chemical and other industries, the main purpose of sewage treatment equipment is to treat domestic sewage and similar industrial organic wastewater to meet the water quality requirements for reuse, so that the wastewater can be reused. Resource utilization after processing.

The so-called primary sewage refers to the direct discharge of untreated domestic or industrial waste water from the city. The current utilization method is that the primary sewage directly enters the sewage source heat pump system for heat exchange, and the indoor cooling and heating of urban buildings are provided under the condition of consuming a small amount of electricity. There are several technical difficulties to be overcome in sewage reuse: clogging, corrosion, heat exchange efficiency.

Recommended Products

Consult Now

If you are interested in our products, please leave your email and we will contact you as soon as possible. Thank you!